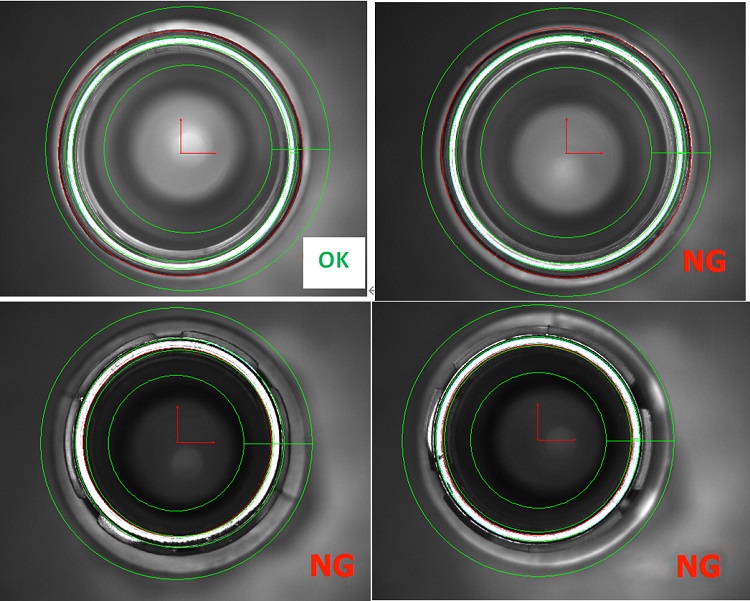

Whether transparent or opaque, big or small - with its 8 cameras, the system can handle any preform.

It guarantees full product safety thanks to a 100% inspection without any blind areas. In addition,

the system is quickly and effortlessly adjustable to your preform portfolio. This leads to huge savings

in time and money when converting to new products.

The preform inspection system can be implemented in your production in different ways: on the one

hand, it can used as an offline system to quickly re-sort preforms of your retained production. On the

other hand, thanks to its linear handling system, the system can also be integrated inline directly behind

the injection molding machine.

Main Specifications:

Samples: